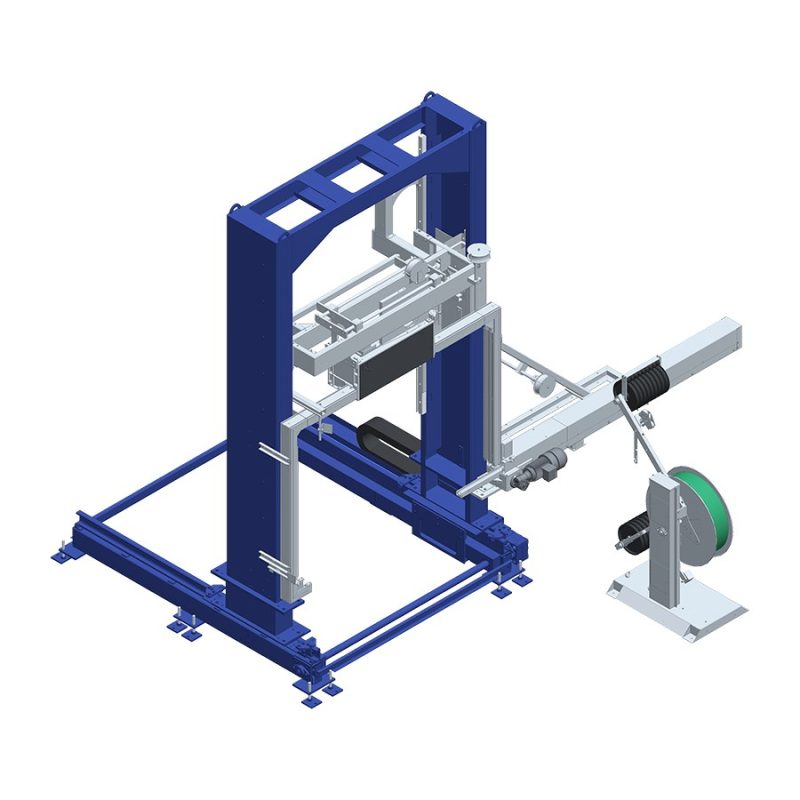

strapping machine service Guidelines for Industrial Efficiency

Maximize Your Packaging Workflow With Specialist Strapping Machine Service Solutions

Optimizing product packaging procedures requires a strategic method to devices upkeep, specifically for strapping machines. Expert service solutions play an important function in improving performance and reliability - strapping machine service. By concentrating on specialist evaluations and safety nets, businesses can attend to concerns prior to they intensify. This positive technique not only boosts efficiency but also decreases prices. Nonetheless, comprehending the subtleties of these services is essential for accomplishing the very best outcomes. What variables should firms think about when selecting a company?

Comprehending the Importance of Strapping Machines in Packaging

Key Advantages of Specialist Strapping Machine Providers

The effectiveness and dependability of packaging operations can be significantly boosted with specialist strapping device services. These services offer experienced upkeep, making certain machines run at peak performance and reducing downtime. By consistently servicing strapping devices, companies can stop unexpected failures, which can interfere with manufacturing routines and result in economic losses. Additionally, professional service technicians have specialized expertise to recognize possible problems early, advertising longer device life-spans. Enhanced operational effectiveness commonly translates to enhanced product high quality, as appropriately functioning equipments safe and secure packages extra successfully - strapping machine service. Such services can adjust to developing packaging demands, offering customized remedies that straighten with manufacturing objectives. Generally, investing in professional strapping device solutions adds to maximized process and enhanced profitability in product packaging operations

Typical Strapping Machine Issues and Solutions

Strapping makers can experience different concerns that affect their efficiency, specifically frequent imbalance issues and strap stress breakdowns. These difficulties can disrupt operations and result in inefficient product packaging processes. Addressing these usual issues without delay is important for keeping peak equipment performance.

Constant Misalignment Troubles

Misalignment concerns are amongst one of the most common obstacles faced by drivers of strapping equipments. These troubles can emerge from numerous elements, consisting of inappropriate setup, deterioration of elements, or a lack of normal maintenance. When a strapping machine is misaligned, it can lead to uneven band application, which endangers the integrity of the plans being safeguarded. In addition, constant imbalance can result in raised downtime, as operators need to continuously change the device for peak performance. To address these concerns, drivers should perform routine inspections, verify appropriate calibration, and replace worn components without delay. By carrying out these best practices, businesses can reduce the threat of misalignment, thereby improving the effectiveness and performance of their strapping operations.

Strap Stress Malfunctions

Operators often encounter band stress breakdowns as a considerable issue in the performance of their machines. These breakdowns normally manifest as insufficient stress throughout the strapping procedure, leading to inadequate or loosened seals. Usual reasons include worn-out tension springtimes, inappropriate calibration, or debris blocking the tensioning mechanism. Additionally, an inconsistent feed price can add to unequal stress circulation, more making complex the strapping procedure. To address these problems, normal upkeep is necessary. Operators ought to inspect and replace worn components, adjust the tension settings according to specifications, and guarantee the machine is cost-free and clean from blockages. Applying these services can boost machine reliability, boost strapping top quality, and inevitably optimize product packaging operations.

Picking the Right Service Provider for Your Demands

When choosing a provider for strapping machine services, what elements should be taken into consideration to ensure peak performance and integrity? Initially, a copyright's experience and experience in the industry are vital, as this guarantees familiarity with various equipment kinds and prospective problems. In addition, assessing client testimonials and endorsements can offer insight right into the More Bonuses company's service quality and responsiveness. It is additionally important to analyze the variety of solutions offered, including setup, fixings, and training, to assure extensive support. Accessibility of extra parts and prompt service feedback times are considerable factors that influence tools uptime. Ultimately, transparent rates and warranty alternatives ought to be gone over to stay clear of unexpected costs, making it possible for businesses to make enlightened choices in choosing their service company.

Preventive Maintenance: Prolonging the Life of Your Equipment

Preventative maintenance is necessary for maximizing the life-span of strapping makers. Executing regular assessment methods, adhering to set up maintenance plans, and making sure cleanliness can greatly reduce the threat of unforeseen malfunctions. These proactive actions not just improve devices integrity yet additionally boost total functional performance.

Regular Examination Practices

Routine assessment practices are essential for preserving the performance and long life of strapping machines, as they assist identify prospective problems prior to they rise right into pricey repair work. These inspections need to include checking critical elements such as the tensioning mechanism, sealants, and motors for damage. On a regular basis examining the machine's positioning and performance warranties peak operation. In addition, keeping an eye on electrical connections and hydraulic systems can avoid unforeseen downtime. Operators should be trained to execute these assessments and paper findings to track efficiency patterns. Executing a culture of routine examinations not just reduces the danger of tools failing however additionally improves overall productivity. By prioritizing routine inspections, companies can guard their financial investment in strapping technology and protected seamless packaging procedures.

Set Up Upkeep Plans

While numerous organizations concentrate on immediate repairs, developing set up upkeep strategies is necessary for extending the life of strapping makers. These plans include routine inspections and servicing that help recognize prospective issues before they rise into expensive malfunctions. By adhering to a predetermined schedule, companies can assure that their tools runs at peak effectiveness, minimizing the risk of unexpected downtime. In addition, scheduled upkeep can improve safety by dealing with damage on parts that could result in accidents. Buying these proactive measures not only lengthens the tools's life-span however additionally enhances performance, ultimately adding to the total cost-effectiveness of packaging procedures. Executing a structured maintenance strategy is a tactical strategy to securing valuable equipment properties.

Value of Sanitation

Tidiness plays a crucial role in the upkeep and durability of strapping equipments. Regular cleansing avoids the build-up of dust, debris, and adhesive residues that can prevent performance and cause early wear. A tidy device operates more successfully, decreasing the chance of malfunctions and costly downtime. Additionally, sanitation extends the life expectancy of essential elements, such as belts and electric motors, by reducing rubbing and stopping corrosion. Implementing a regular cleansing timetable is look at here now crucial for drivers to ensure peak capability. This positive method not only enhances productivity yet additionally cultivates a much safer working atmosphere. Inevitably, focusing on sanitation pop over to these guys within packaging operations can lead to significant expense savings and improved total efficiency of strapping devices.

Modification Options for Optimal Efficiency

Just how can services assure that their strapping devices operate at peak efficiency? Personalization alternatives play an important duty in enhancing performance. By customizing strapping machines to certain operational needs, companies can optimize stress, speed, and band width, ensuring compatibility with different product packaging materials. Additionally, incorporating sophisticated technology, such as automated feeding systems and straightforward user interfaces, improves total performance. Services can additionally choose in between various strapping materials, such as polypropylene or polyester, based on resilience and cost-effectiveness. Routine assessments of production needs allow firms to change their strapping options, adapting to changes in product dimensions and weights. Eventually, customized strapping equipments bring about minimized downtime and raised productivity, placing organizations for success in affordable markets.

Gauging the ROI of Strapping Machine Providers

When examining the roi (ROI) of strapping machine services, services have to consider several elements that add to overall effectiveness and price savings. Crucial element include the decrease in labor prices as a result of automation, lowered material waste, and enhanced product packaging speed. Reputable service guarantees very little downtime, permitting operations to maintain performance levels. In addition, the longevity of strapping equipment can substantially impact ROI; routine upkeep and timely repairs prolong device lifespan, resulting in lower replacement expenses. Boosted product protection with appropriate strapping likewise lowers damages during transportation, more saving cash. By analyzing these aspects, business can gain a complete understanding of exactly how specialist strapping machine solutions straight affect earnings and functional success.

Regularly Asked Concerns

How Commonly Should I Schedule Strapping Machine Service?

Strapping equipment service ought to generally be set up every six to twelve months, depending on usage strength. Normal maintenance assurances peak performance, expands device life, and minimizes unanticipated break downs that might interrupt packaging procedures.

What Sorts Of Strapping Materials Can My Machine Use?

Strapping machines can use different products, including polypropylene, steel, and polyester strapping. Each kind uses different tensile toughness and applications, allowing organizations to pick the most suitable choice based upon their product packaging demands and needs.

Exist Service Warranties Available for Strapping Machine Providers?

Guarantees for strapping machine services are commonly offered, differing by service provider. They typically cover components and labor, making certain repair services or substitutes within a specified period, therefore offering assurance for operational dependability.

Can I Do Maintenance on My Strapping Machine Myself?

Yes, upkeep on strapping devices can often be executed by the individual. It is essential to comply with the producer's guidelines and security methods to ensure effective maintenance and stay clear of possible damage or breakdown.

Exactly how Do I Know When to Change My Strapping Machine?

Indications to replace a strapping machine consist of frequent break downs, inconsistent strapping top quality, extreme wear, and outdated innovation. strapping machine service. Checking efficiency and maintenance costs can help determine when acquiring a new device becomes extra economical than fixing the existing one

The performance and integrity of product packaging operations can be considerably boosted with expert strapping device services. By routinely servicing strapping devices, businesses can prevent unforeseen failings, which can disrupt manufacturing routines and lead to economic losses. By tailoring strapping devices to details functional needs, companies can optimize tension, speed, and band width, making certain compatibility with numerous packaging products. Additionally, the durability of strapping tools can substantially affect ROI; regular maintenance and prompt repair services prolong maker life expectancy, resulting in reduced substitute expenses. Signs to change a strapping equipment consist of regular breakdowns, irregular strapping quality, excessive wear, and outdated modern technology.